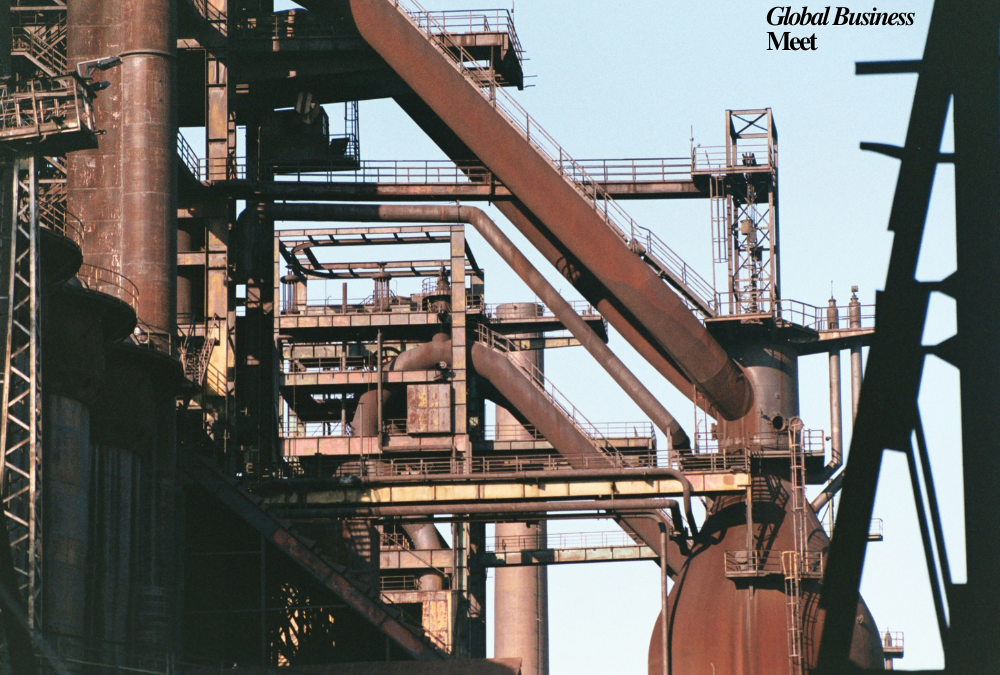

In an attempt to cut down carbon emissions that are linked with the production of concrete. PHNX Materials is a decarbonizing the concrete industry firm has found a method of utilizing fly ash generated by power plants that have coal, otherwise a waste. With a view to alleviating relief to the settlement of material deficiencies in the construction sector and increasing the well-being of the environment PHNX intends to sanitize this material and substitute a significant quantity of cement in concrete mixtures.

Fly ash has been employed since centuries to add strength and hardness to concrete. But as it includes contaminants in the guise of carbon and sulfur its usage has been besmirched. The PHNX new process all these contaminants erases quite well, hence the fly ash finds itself apt to be applied within concrete. This technology provides a sustainable alternative to cement responsible for approximately 8% of global CO₂ emissions, and a solution to the dwindling supply of quality fly ash, a waste product of the decommissioning of coal fired power stations.

The company collects fly ash straight from landfills, purifies it of contaminants and sells the purified ash to cement companies. Besides landfill waste capping and this lowers the use of conventional cement hence decreasing greenhouse emissions. Additionally, the purification process creates possibilities for potential future industrial utilization through recovery of valuable materials such as sulfur and aluminum.

PHNX Materials has just raised $2.5 million in seed funding co-led by Divergent Capital, Overture and KdT Ventures with the backing of investor Jane Woodward as a sign of confidence in its revolutionary solution. The firm will utilize the investment to scale operations and grow its contribution to sustainable building.

PHNX Materials is a perfect example of how new technologies can best be used to address environmental issues. At the same time, creating economic growth through the conversion of an unwanted waste byproduct into something valuable. With the building industry trying to minimize its carbon footprint such technologies are of invaluable potential in leading sustainable building practices.