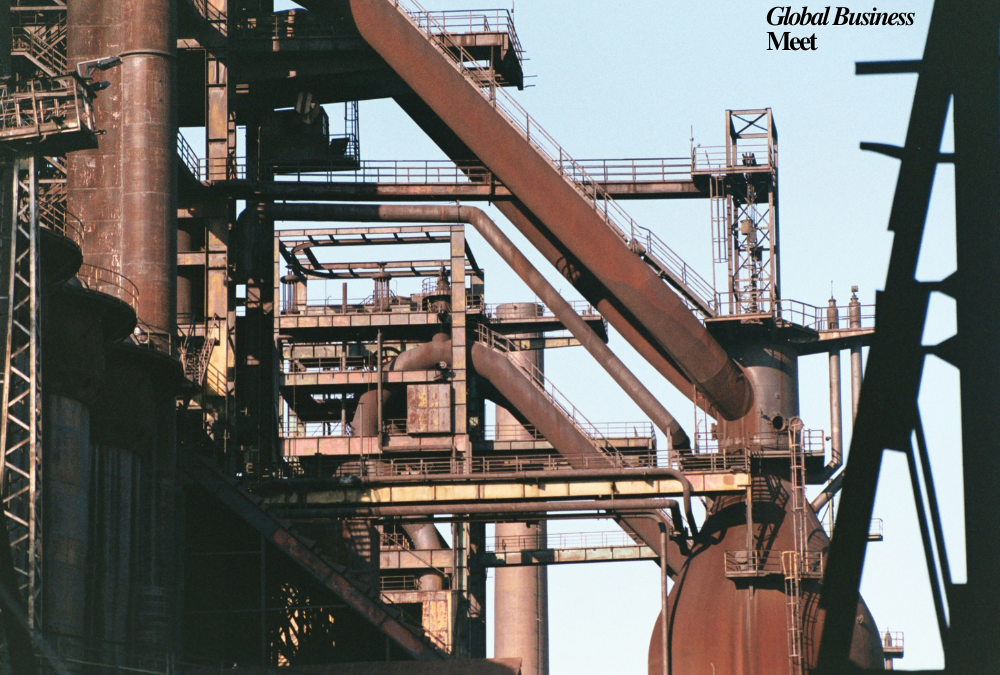

Electra which refers to its backers as pioneering industrial startups has raised $186 million in Series C funding to help transform iron production by coming up with a clean, modular process that produces 99% pure iron using intermittent renewable energy and low-grade iron ores. The idea of this novel approach is to make a huge reduction in carbon emissions and resource intensity in ironmaking, a process responsible for about 10 percent of all global CO₂e emissions.

Innovative Technology for Sustainable Iron Production

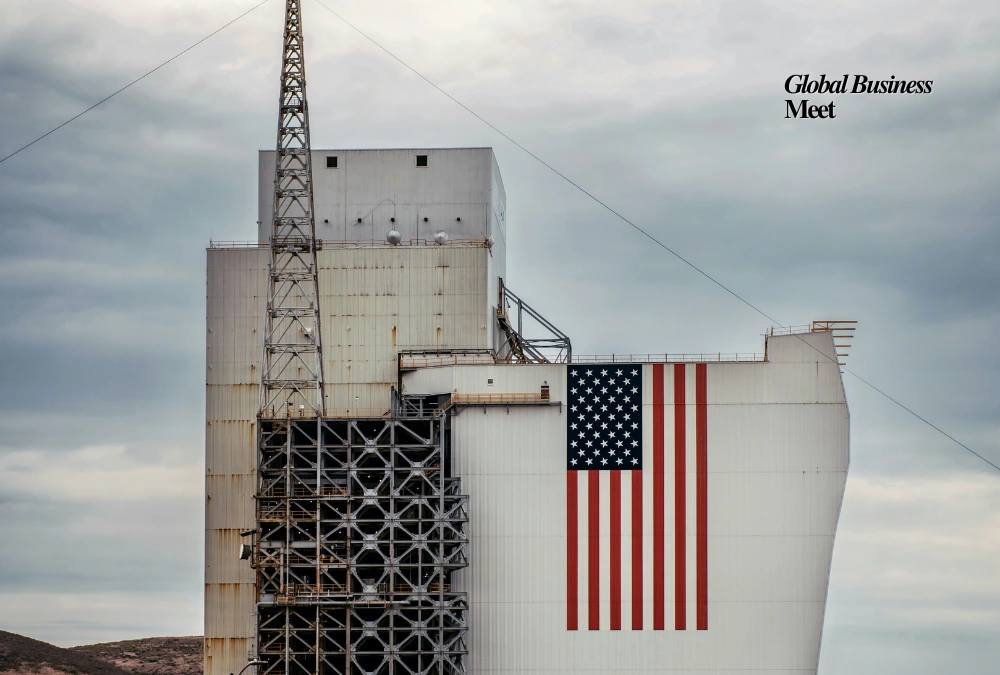

Energy intensive and requiring large amounts of the fossil fuels, the traditional ironmaking process is responsible for a massive amount of industrial greenhouse gas emissions. Electra’s breakthrough technology resolves these challenges with the use of renewable energy sources and low-grade iron ores that are frequently underutilized in the conventional methods. The company’s modular system is designed to be scalable and adaptable to the integration in existing industrial infrastructures and towards more sustainable practices in the iron and steel industry.

Strategic Funding to Accelerate Growth

Prominent investors, including Breakthrough Energy Ventures and Lowercarbon Capital, led the recent funding round and a number of strategic partners dedicated to developing clean technologies took part in the round too. Electra will be able to use this substantial investment to expand, increase the technological capabilities and accelerate the commercialization of its innovative ironmaking process. By using the funds, the company plans to expand pilot projects across the globe, and enter into partnerships with the most important players in the industry, as well as develop its technology to catch up with the demand for sustainable industrial solutions.

Electra’s Vision for Sustainability

Electra is on a mission that corresponds with global efforts to decarbonise heavy industries and reduce the effects of climate change. Electra seeks to have a major positive exosphere impact by offering a more environmentally friendly route to ironmaking than the traditional methods that have the most carbon impact of any industrial process. Apart from environmental considerations, the company’s creative solution incorporates employing available low grade iron ores and renewable energy sources, potentially lowering production costs and improving resource efficiency.

Implications for the Iron and Steel Industry

If Electra’s technology is implemented successfully, it could establish a new benchmark for sustainable radiations throughout the iron and steel industry. With almost a perfect circularity and increasing demand for clean ironmaking process that is also environmentally friendly and cost effective, Electra stands as the right option to the traditional methods. Such advancements by the company may spur further innovation and investment in sustainable industrial technologies in general to bring the net zero emission goal for broader sector.

Looking Ahead

Electra is poised to use the backing of significant investment and a well defined way forward to change iron production for good. As a major company in the transition from an unsustainable industrial economy to a sustainable one, sustainability, scalability and innovation are what the company has pledged to, and can fulfill. The expanding capabilities and improving technology of Electra make the possibility of adoption increasing, growing hope that ironmaking and more will become cleaner, more sustainable.