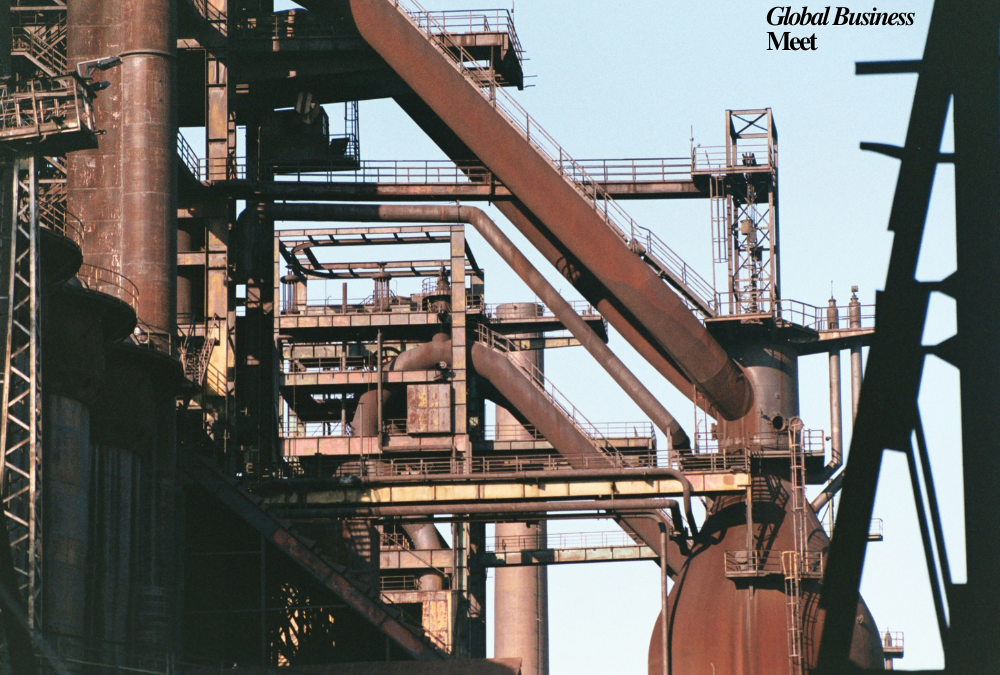

The startup PHNX Materials developed a startup to decarbonize the concrete industry, which created a way to turn coal plant fly ash waste into concrete components and cut the emissions. The success of PHNX is to improve its product for use as the cement replacement material in concrete mixes. The company addresses two important environmental problems and two important material shortages in the construction sector by solving them.

Fly ash has been confirmed by science as beneficial in terms of providing advantageous traits in concrete that makes concrete durabler. The imperfections in the material mainly comprise sulfur and carbon content forced the PHNX industrial application to remain frozen. At PHNX the contaminants of fly ash are effectively cleaned in the innovative process until the ash is ready for use in concrete mixtures. The existence of both a eco friendly cement replacement and a replacement for the dwindling supply of high quality fly ash (resulting from the planned shutdown of power plant plants) is one of the advantages of the PHNX process.

The operations of the company are the supplying towards concrete manufacturers of fly ash processed from fly ash from landfills and elimination of unwanted substances of fly ash before the processing of fly ash. Preventing landfill accumulation and lowering cement use to minimize environmental gases result in lower environmental gases due to this waste management method. At the end of the process sulfur is extracted along with aluminium.

Pioneering approach propelled PHNX Materials past $2.5 million in seed funding from Divergent Capital. KdT Ventures, Overture and an investor Jane Woodward. The received capital lets the company perform operational growth and expand more of its sustainable backing into the market.

By enabling transition of problematic waste to valuable resources. PHNX Materials proves successful innovation of how environmental solutions merge with economic growth. In such advanced solutions, construction leaders and leaders in the building practice can seek hope for sustainability.